Focus & Commitment to Bring High Quality Solution

Tooling Manufacturing Methods

Till the year 2000, in india , the foundry tooling were being made only through manual / conventional methods. Carpenters by profession were considered to be the best foundry pattern makers.

Tentatively from the year 2000, cnc route of tooling manufactuiring has been developed in india in a big way and today more than 60 % of the foundry tooling are manufactured only through this method

We, ”M/s Sri Andal Engineering Works‘’ are one of the major tooling manufacturer through cnc route, in south india.

Following Considerations are made prior to the Commencing of the Tooling Design

- Casting geometry

- Casting size/weight

- Casting requirements per month /annum

- Casting manufacturing process

- Casting quality requirements in terms of dimensions and internal soundness

- Most economical way of producing the part

- Maximum out put per mould

- Field application of casting

Steps involved in the Conventional Method of Tooling Manufacturing Process

- Study the hand drawn drawings and decide the parting line

- Prepare hundreds of templates in paper, aluminium sheet to 1:1 scale

- Prepare 1:1 tooling lay out on a sheet of paper / sheet

- Build the pattern, make the master pattern manually and pour the master castings in case of metal patterns

- Machine the patterns to the nearest drawing profile.

- Manually work on the each profiles and finish to the templates on each sections

- Inspect the patterns on the surface table with marking and measuring instruments

Steps involved in the CNC Route of Tooling Manufacturing

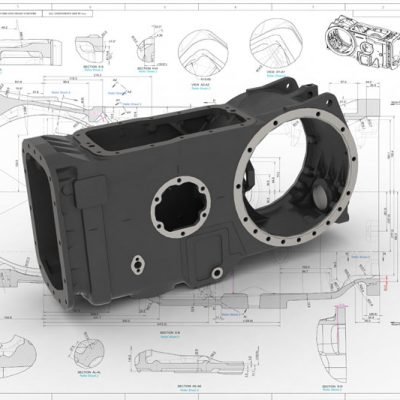

- Study the 2D drawing and decide about the basic things line parting line to be taken, no of core boxes etc.

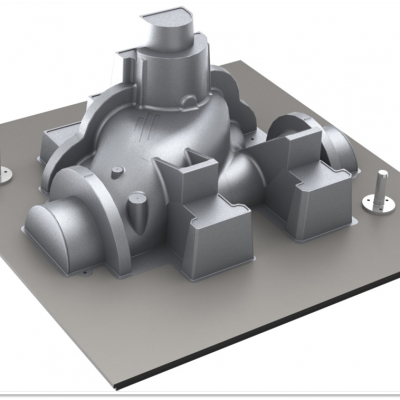

- Prepare the 3D model by using softwares like , solid works,pro e, catia, ideas unigraphics etc.

- Update the model by providing the drafts and fillets , allowances such as contraction machining etc based on the parting line decision

- Verify the 3D model with respect to the 2D drawing and approve.

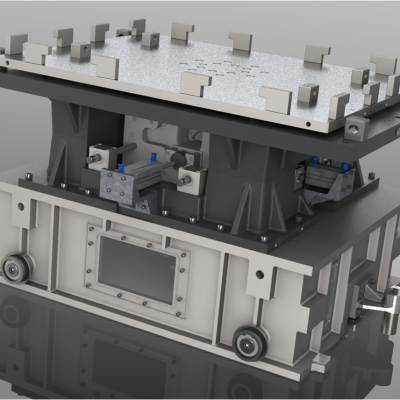

- Design the pattern and core boxes

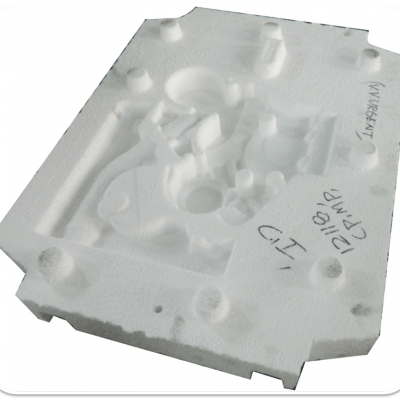

- Manufacture the master patterns and core boxes by machining on a cnc machine either using wood or thermocol

- Pour the master casting and pre machine

- Carry out the machining programmes using softwares like cimetron, delcam,ug,etc.

- Machine the pattern and core box profiles automatically as per the machining programme

- Finish polish the tooling manually by using polishing wheels

- Mount the patterns on a match plate as per the finalised pattern lay out and fix the gating systems

DESIGN SERVICES